Highlights

- Biodegradable sandbags exist and are widely used in landscaping, construction, and the oil and gas industries.

- They are made from jute (called burlap once woven), and they’re perfect for short-term water prevention applications or for heavy-duty construction projects where users can leave them in place at the end of the project. Jute bags are made with the fibers of the Corchorus plant, and as a natural material will decompose over time.

- Burlap sand bags are better for the environment because they are biodegradable, meaning that they naturally decompose over time; however they generally will not last as long as a synthetic sand bag if left exposed to the elements. Jute bags can last for up to a year if kept in favorable conditions. Things like how much it receives abuse and where it is used will affect a burlap sandbag’s lifespan.

Are There Biodegradable Sandbags?

Biodegradable sand bags do exist, and they’re used widely in a variety of industries, most commonly in landscaping, construction, and the oil and gas industry.

They’re generally made from jute, woven into the material known as burlap.

Because they break down over time, they’re perfect for applications where you don’t want synthetic materials left behind, or when the bag’s disappearance over time may even be ideal! Biodegradable sand bags are also great for people or organizations looking for compelling, natural alternatives to plastics.

The question is whether they are strong and durable enough to be used as sandbags for your particular application.

Jute and Burlap Bags as Sandbags

Biodegradable sandbags are usually made from the natural material jute, and are thus biodegradable. This is why they are often used in the oil and gas industry: they can be buried in the ground to cushion underground pipelines and then left there to decompose.

Their biodegradability also makes them ideal for short-term applications such as building flood barriers or temporary barricades. Biodegradable burlap sandbags are great for landscaping needs too, often to hold or create an earth berm or for erosion control during a major landscaping project.

Use cases for biodegradable jute bags include:

- Construction projects, for erosion control around and on the job site. Over time, these bags simply break down and return to the earth, ideally in the same timeframe that the project is complete, making cleanup a breeze.

- Landscaping needs, for holding back soil temporarily or for water and erosion control during and after the project. Again, because they disappear with time, they make a great solution that then blends into the planned landscaping project, or they can be removed manually.

- In pipeline construction, burlap sandbags are used extensively to cushion and position a large oil or natural gas pipe when it’s laid in the ground. The fill can then be replaced, the pipeline covered, and the bags left in place where they will naturally degrade with time.

Biodegradable Sandbags Vs. Traditional Sandbags

You might be wondering if jute sandbags are just as durable as plastic bags.

Short answer: no.

Sandbags deployed at scale in flood prevention are generally made of polypropylene or polyethylene. These are synthetic plastics that are extremely flexible and durable, which is useful when using sandbags to protect doors, build flood barriers, or other heavy-duty applications. However, these bags are not biodegradable, which means that they may pollute the environment for long after they’ve outlasted their purpose.

But traditional woven polypropylene sand bags can last for 2-5 years depending on material thickness and UV-resistance. For long-term sandbag applications, they’re generally a superior product.

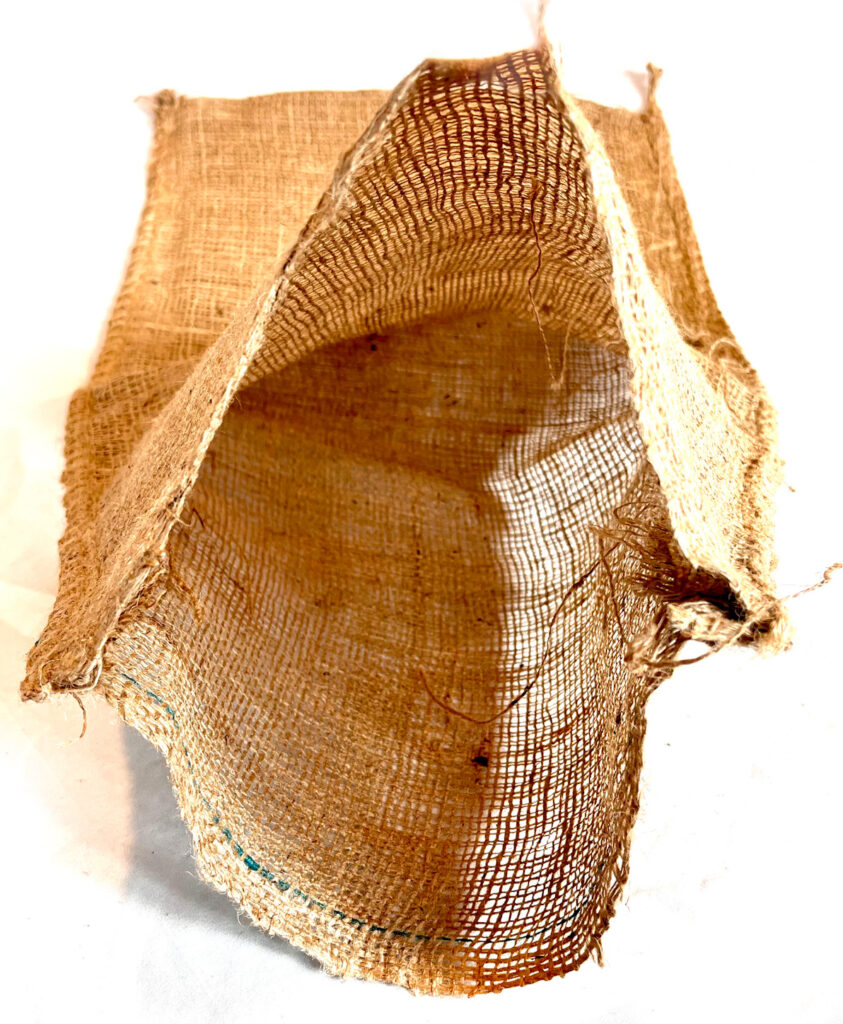

The consensus is that while burlap sand bags are tough and as useful as synthetic sandbags – forming a great water barrier and conforming to the terrain, objects, or a sandbag wall very well – they simply won’t last as long. The primary reason: moisture is the enemy of burlap. Moist or wet jute rots, and in most ground-contact uses, that means their lifespan will be around 12 months.

What Size Burlap Bags for Sandbags?

A standard sandbag (and the one deployed by the US Army Corps of Engineers) is 14 inches by 26 inches. This will typically hold around 40 pounds of sand and is the ideal size for versatility.

Burlap sand bags are commonly available in 13 x 24 inch dimensions and larger. (Our 24″x40″ burlap bag is great as a sack race bag!)

These dimensions provide a balance between versatility and ease of transport, so they are widely used for many different applications. However, more heavy-duty applications such as erosion control for large projects may require larger-sized sandbags. Sandbags used for construction purposes are sometimes up to 24 inches by 40 inches in size and can hold dozens of pounds of sand.

Where Jute Plants and Jute Materials Come From

Burlap bags, sometimes called hessian bags, are made using jute fibers, which come from the jute plant, scientifically known as Corchorus. This plant is primary grown in tropical and subtropical regions of Asia, particularly in countries like Bangladesh and India.

Manufacturers use several species of plants for making jute bags, but the fibers of the Corchorus Capsularis plant are generally considered to be the best. Jute bags need to be durable yet flexible, which means that high-quality fibers is a must. This jute plant is recognized for its long, soft, and shiny fibers, which are harvested to produce burlap, hessian, or gunny cloth.

The cultivation of this plant is generally considered environmentally friendly, as it doesn’t require many synthetic additives and replenishes quickly. This another reason that jute bags have a low environmental impact compared to plastic or poly bags: fewer man-made inputs.

The jute plant grows quickly and is harvested within six months. As it grows, it forms long fibers under its bark that are then extracted to form jute bags. Once harvested, the plant is soaked in water to allow for the fiber bundles to separate from the stem and bark. After they separate, the fibers are graded based on quality and sorted for their many different applications.

Jute bags are then made by creating strings of dried fiber and weaving them together into a tight or coarse fabric that is then cut and stitched together into the shape of a bag – in this case, a standard sand bag profile.

The importance of jute goes beyond how useful it is for biodegradable sand bags. Their production aligns with environmentally friendly practices, making them a great choice if you’re looking for an eco-friendly alternative to polypropylene sandbags.

FAQs

How long do burlap sandbags last?

Burlap sandbags can be expected to last about a year depending on precise conditions and use. This depends on factors like how exposed to the weather the bag is, where it is stored, or how often it is emptied and refilled.

Jute rots when it remains moist, and because it is a natural material it actually becomes food for worms and common ground-dwelling organisms. For this reason, biodegradable jute sandbags used as a flood barrier should only be considered for short-term applications.

By contrast, UV-resistant polypropylene sandbags can last for as long as five years in the outdoors.

Are burlap sandbags good for flooding?

While jute bags can be used for flooding and will work as well as plastic counterparts in diverting water, they should not be expected to last as long.

If your flood prevention needs are short-term, and you value the fact that burlap breaks down with time, they can be great.

If you expect to leave your sandbags in place for more than a year, there are better (though less environmentally friendly) sandbag options.

Also note that coarsely woven burlap sandbags may not hold sand, gravel, or fill material as well as a tighter weave.

How should I store burlap sandbags?

Burlap sandbags should be left in a dry, cool place away from sunlight. This will ensure they don’t decompose early due to exposure to the elements.

Are burlap bags cheaper than polypropylene sandbags?

Synthetic bags are usually more cost-effective than biodegradable sand bags.

What is the difference between jute and burlap?

Jute is the fiber that becomes burlap once woven.

Looking for biodegradable sandbags in Canada?

That’s what we do. Based in Manitoba, we’re Canada’s choice for woven bags of all kinds. Learn more and order biodegradable sandbags in bulk today.